Rigging Hardware

(Total 8 Products)-

Min. Order:1Product Description Adjustable Height Truss Base: The Core Cornerstone of Flexible Stage Construction In the dynamic field of stage construction, where every detail affects the overall effect and safety of the event, the Adjustable Height Truss...

-

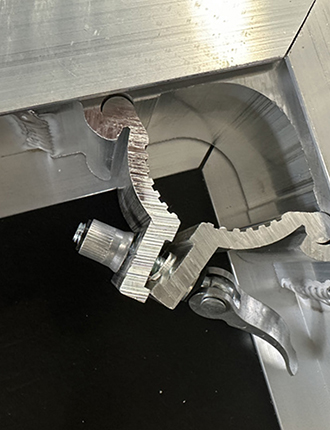

Min. Order:1Truss Connector Hardware for Rigging & Scaffolding: The Invisible Hero Securing Stage Structures In the intricate ecosystem of stage construction, where every beam, platform, and support must work in perfect unison, Truss Connector Hardware for...

-

Min. Order:1Adjustable Height Truss Base: The Core Cornerstone of Flexible Stage Construction In the dynamic field of stage construction, where every detail affects the overall effect and safety of the event, the Adjustable Height Truss Base has emerged as a...

-

Min. Order:1Professional Truss Rigging Solution for Lighting: Empowering Brilliant Stage Visuals with Premium Components In the world of live performances, events, and entertainment, lighting is not just a tool to illuminate the stage—it is a storyteller that...

-

Min. Order:1Stage & Lighting Truss Leveling Base: The Cornerstone of Building a Dream Stage Revealing the Secrets of Stage Construction MaterialsIntroduce the importance of stage construction materials to the performance effect, and lead to the materials to...

-

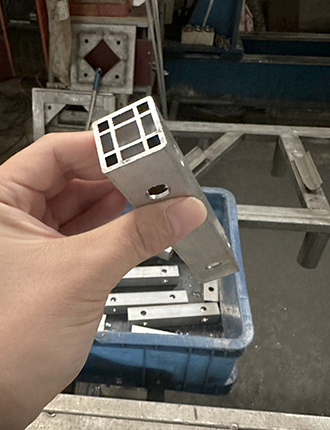

Min. Order:1The Ultimate Link for Superior Structures: Square Truss Connector - Heavy Duty Aluminum CouplerIn the world of stage and truss systems, every connection matters. The integrity of the entire structure depends on the strength and reliability of the...

-

Min. Order:1Core Hub, Forging Extraordinary Stages: Heavy-Duty Square Head JointBehind every breathtaking performance and beneath every stage that carries passion and creativity, lies a silent yet powerful support system. And the starting point of all this...

-

Min. Order:1Unlocking the Mystery of Stage Construction: The Choice for Aluminum Truss Connection Revealing the Secrets of Stage Construction MaterialsBriefly describe the characteristics of different stage construction materials, such as the portability of...

Rigging Hardware encompasses the critical components and equipment used to securely lift, lower, suspend, and move heavy loads. These devices form the essential link between a load-bearing structure (like a Truss or beam) and the object being supported, making them fundamental to safety in industries such as entertainment, construction, manufacturing, and maritime operations.

The category includes a wide array of forged and machined items, each with a specific function. Key examples are:

Shackles:U-shaped connectors secured by a pin, used to join slings, ropes, or other hardware.

Turnbuckles:Adjustable devices for tightening and tensioning cables or rods.

Eye Bolts and Lifting Points:Threaded bolts with a looped head, used to create a secure attachment point on a load or structure.

Wire Rope Clips and Swage Sockets:Devices used to create permanent or semi-permanent loops (eyes) in wire rope.

Load Rings and Hooks: For connecting to and suspending loads.

The paramount consideration for all rigging hardware is safety. Every component is rigorously engineered and rated with a Working Load Limit (WLL), which is the maximum mass or force it is designed to support under normal service conditions. This rating is distinct from the ultimate breaking strength and includes a significant safety factor. Proper selection, regular inspection for wear or deformation, and correct use are non-negotiable to prevent catastrophic failure.

In essence, rigging hardware is the unsung hero of load management. These small but mighty components bear immense responsibility, and their integrity is the foundation of safe overhead lifting and suspension practices in countless professional fields.

The category includes a wide array of forged and machined items, each with a specific function. Key examples are:

Shackles:U-shaped connectors secured by a pin, used to join slings, ropes, or other hardware.

Turnbuckles:Adjustable devices for tightening and tensioning cables or rods.

Eye Bolts and Lifting Points:Threaded bolts with a looped head, used to create a secure attachment point on a load or structure.

Wire Rope Clips and Swage Sockets:Devices used to create permanent or semi-permanent loops (eyes) in wire rope.

Load Rings and Hooks: For connecting to and suspending loads.

The paramount consideration for all rigging hardware is safety. Every component is rigorously engineered and rated with a Working Load Limit (WLL), which is the maximum mass or force it is designed to support under normal service conditions. This rating is distinct from the ultimate breaking strength and includes a significant safety factor. Proper selection, regular inspection for wear or deformation, and correct use are non-negotiable to prevent catastrophic failure.

In essence, rigging hardware is the unsung hero of load management. These small but mighty components bear immense responsibility, and their integrity is the foundation of safe overhead lifting and suspension practices in countless professional fields.