Cuplock Scaffolding

(Total 8 Products)-

Min. Order:1Ringlock scaffolding is an advanced cup-lock scaffolding system, so named for the unique circular rosette design at its nodal joints. Scaffolding It ranks among the most robust, safe and efficient modular scaffolding systems currently available. It...

-

Min. Order:1Heavy-duty portal scaffolding is specialized supporting gear built for construction work that calls for high load-bearing capacity and stability. Made with a high-strength steel core structure, ordinary portal scaffolding hands down in load-bearing...

-

Min. Order:1Heavy-Duty Cuplock Scaffolding: The Unshakable Core of Your Most Demanding ProjectsWhen your project involves the immense weight of a Steel Truss System or the expansive requirements of a full Raya Stage System, ordinary support simply won't...

-

Min. Order:1Hot-Dip Galvanized Cuplock Scaffolding: The Corrosion-Resistant Backbone for Lasting StructuresEvery iconic event begins with a foundation that can withstand more than just weight—it must endure the elements. While the spotlight shines on the...

-

Min. Order:1Temporary Stage Scaffolding Systems for Construction: The Unseen Foundation of Every Grand StageBefore the applause and the spotlight, there is the blueprint. Before the performers and the production, there is the construction. For any temporary...

-

Min. Order:1Adjustable Base Cuplock Scaffolding: The Solid Foundation for Grand Structures Before the spotlight hits the Aluminum Alloy Plug-in Stage and the first note echoes from the Raya Stage System, a silent, robust foundation is already in place. For...

-

Min. Order:1Aluminum Cuplock Scaffolding System: The Safe Foundation and Flexible Support for Stage ConstructionThroughout the entire stage construction process, the support system is a core link that ensures safety and efficiency. The Aluminum Cuplock...

-

Min. Order:1Galvanized Cuplock Scaffolding Systems: The All-Round Partner and Preferred Matching Option for Engineering Construction In scenarios such as large-scale performance setup, engineering construction, and event arrangement, a safe, stable, and...

Cuplock Scaffolding is a highly versatile and robust Modular Scaffolding system, renowned for its efficiency, high load-bearing capacity, and speed of assembly. It is a leading choice for a wide range of heavy-duty applications in construction, industrial maintenance, and infrastructure projects worldwide.

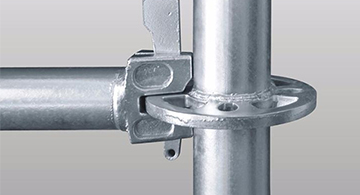

The system's defining feature is its unique node connection point. Vertical standards (uprights) have welded steel cups fixed at predetermined intervals. Horizontal ledgers are then connected using a patented blade-end fitting. This blade is inserted into the cup on the standard, and a separate wedge is driven down with a hammer to lock the components securely together. This creates a rigid, moment-resistant node without the need for loose nuts, bolts, or complex tools.

Key advantages of the Cuplock system include:

Rapid Assembly: The simple hammer-action locking mechanism allows for significantly faster erection and dismantling compared to traditional tube-and-coupler systems.

Inherent Safety: The wedge-lock design creates a highly secure connection that is resistant to accidental dislodgement, and the system's inherent strength provides a stable working platform.

High Load Capacity: Its design is optimized for heavy loads, making it suitable for supporting concrete formwork, access towers with material storage, and large façade scaffolds.

Modularity and Versatility: The system can be configured as standard access Scaffolding, heavy-duty shoring towers, support bridges, and complex geometric structures.

In essence, Cuplock Scaffolding represents a significant evolution in scaffolding technology, offering a blend of speed, strength, and safety that makes it a preferred solution for demanding professional construction environments where productivity and reliability are critical.

The system's defining feature is its unique node connection point. Vertical standards (uprights) have welded steel cups fixed at predetermined intervals. Horizontal ledgers are then connected using a patented blade-end fitting. This blade is inserted into the cup on the standard, and a separate wedge is driven down with a hammer to lock the components securely together. This creates a rigid, moment-resistant node without the need for loose nuts, bolts, or complex tools.

Key advantages of the Cuplock system include:

Rapid Assembly: The simple hammer-action locking mechanism allows for significantly faster erection and dismantling compared to traditional tube-and-coupler systems.

Inherent Safety: The wedge-lock design creates a highly secure connection that is resistant to accidental dislodgement, and the system's inherent strength provides a stable working platform.

High Load Capacity: Its design is optimized for heavy loads, making it suitable for supporting concrete formwork, access towers with material storage, and large façade scaffolds.

Modularity and Versatility: The system can be configured as standard access Scaffolding, heavy-duty shoring towers, support bridges, and complex geometric structures.

In essence, Cuplock Scaffolding represents a significant evolution in scaffolding technology, offering a blend of speed, strength, and safety that makes it a preferred solution for demanding professional construction environments where productivity and reliability are critical.

WHY CHOOSE US

Efficient connection and convenient construction

The combination of ring locks and wedge-shaped pins requires no bolts or tools. Fixing can be completed only by manual tapping, and disassembly is done by pulling out the pins. The assembly efficiency is 3-5 times that of traditional coupler-type scaffolding. A team of 2-3 people can build a large-scale support structure within a few hours.

Stable structure and extremely strong load-bearing...

Crossbars and diagonal bars form multiple triangular stable structures through ring locks, resulting in outstanding overall anti-overturning and anti-shearing capabilities. A single vertical pole can bear a load of 5-10 tons. Combined with the high strength of steel, it is widely used in high-load-bearing scenarios.

Modular expansion, suitable for large-span scenarios

The rods are produced in a standardized way and can be infinitely spliced according to needs, supporting the construction of super-large-span and super-high structures, such as the main stage framework of large concerts, the support for temporary stands in stadiums, and the load-bearing brackets for bridge construction.

Strong durability and adaptability to complex...

Steel components are galvanized or painted, which are corrosion-resistant and wear-resistant, and can adapt to outdoor environments such as rain and snow, high temperature, and humidity. Even with long-term use, as long as the connectors are checked regularly, the service life can reach 10-20 years, with low maintenance costs.

Adjustable Base Cuplock Scaffolding

Hot-Dip Galvanized Cuplock Scaffolding

Stage Erection Scaffolding System

Heavy-Duty Cuplock Scaffolding design